Kachelöfen (sing. Kachelofen) are a class of Grundöfen. Grundöfen are better known in North America as a specific style of masonry heaters (or thermal mass heaters). Thermal mass heaters are incredibly fuel efficient heating systems that capture heat created from the burning of a fuel source (usually wood). The heater then radiates at a fairly constant temperature over a long period of time. Thermal mass heater technology has existed for millennia. Archeological evidences of ancient peoples capturing hot smoke from fires to radiated into living spaces dates back to the Neoglacial and Neolithic periods.

Thermal mass heater technology has been evolving ever since then!

What is a Kachelofen?

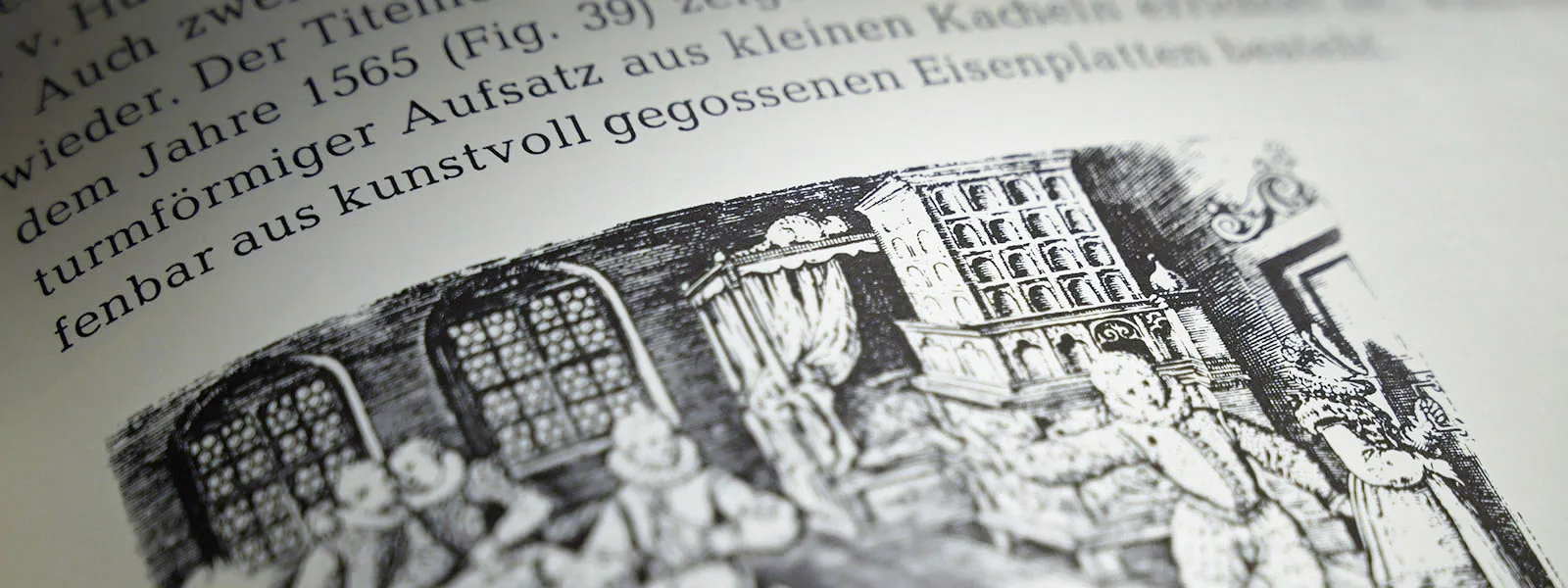

At SHKO we make Kachelöfen. Kachelöfen as we know them were first developed and refined during the Renaissance period in Germany, where a a distinct trade of oven building specialists developed called hafnermeister.

Kachelöfen differ from other thermal mass heaters because the outer layer of the stove is made up of ceramic Kacheln. Kacheln may look like tiles – this style of oven is often referred to as a tile stove – but they are actually three dimensional brick-like building blocks used to construct the outer layer of the oven.

During the construction process the Kacheln are backfilled with firebrick and mortar to add mass and to help evenly distribute heat.

Kacheln are used to build the outer 5 cm (2”) of the stove. The inside of the stove is made up of a fire chamber and a complex flue system made of firebrick and mortar. The outer layer of Kacheln is built first, and then the inner core of firebrick follows along as the stove is built upwards.

What are the Characteristics of a Kachelofen?

The outside of a Kachelofen is made of ceramic. The firebrick interior consists of two main components. A firebox takes up a large portion of the lower half of the stove. A complex flue channel winds back and forth above this. The flue path creates additional firebrick surface area which absorbs the heat from the exhaust gases as they slowly make their way into the chimney.

Kachelöfen have several advantages over a traditional metal wood burning stove:

- radiant heat has a gentler quality and does not lead to extreme dryness

- a much hotter burn results in significantly lower emissions

- no dust

- the exterior of the stove never gets too hot to touch

- safer

- meets strict emission standards

- ash from the firebox only need to be removed a few times times per heating season

How to use a Kachelofen

Firing a Kachelofen is different than a standard North American metal wood stove. In a Kachelofen the fire should be burned as hot and as quickly as possible using a “top down burn.” The burning wood heats the considerable mass of the stove.

Once the wood is reduced to orange glowing embers and blue flames, then the damper is closed and the oven is “locked down.” The heat is then trapped inside the oven. Over the next several hours the heat from the smoke and gases slowly snakes its way through the firebrick flue channel, and begins to radiate outward through the mass of the stove.

A Kachelofen will capture the heat from a single fire and slowly release it over the course of eight to twelve hours.

What is a Masonry Heater?

A contemporary masonry heater is a vented heating system of predominantly masonry construction having a mass of at least 800 kg (1,760 lb), excluding the chimney and masonry heater base. In particular, a masonry heater is designed specifically to capture and store a substantial portion of the heat from a solid fuel fire in the mass of the masonry heater through internal heat-exchange flue channels, to enable a charge of solid fuel (mixed with an adequate amount of air) to burn rapidly and more completely at high temperatures, in order to reduce emission of unburned hydrocarbons, and be constructed of sufficient mass and surface area such that under normal operating conditions, the external surface temperature of the masonry heater (except in the region immediately surrounding the fuel loading door(s)) does not exceed 110 °C (230 °F).

As defined by ASTM International