Jessica was a guest at the Masonry Heater Association of North America again! As always, the conference was held at the Wildacres Retreat conference center near Asheville, North Carolina from April 10-16. Jessica represented Stone House Kachelöfen all week at the annual event. She led a workshop on how to assemble a kachelöfen.

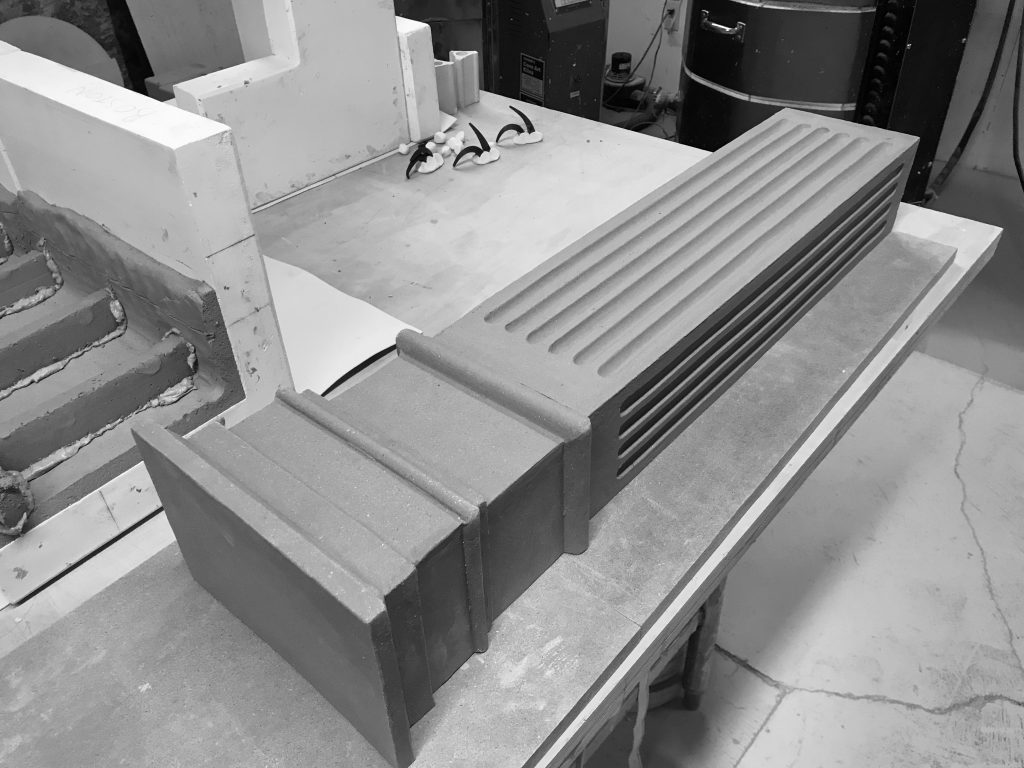

The Muskoka Kachelofen is a small freestanding Kachelofen/Grundofen. It is named after a regional municipality in Central Ontario that is famous for its lake houses, cottages and stunning wilderness. The footprint of this stove is remarkably compact at only 63cm x 53cm x 208cm (24in x 20in x 80in). It is available in a number of colours. The demo unit will be glazed in a gorgeous deep green colour.